Monitoring

HGS personnel have developed and refined measuring techniques to define and quantify the effect of heterogeneity on reactive solute transport. Experience on environmental remediation and metal leaching industry reveals that reagent delivery is the limiting step on the efficiency of these processes.

Similarly, the lack of knowledge of the porous medium (aquifer or rock pile) heterogeneity has forced practitioners to treat porous media as black boxes rather than as “field-scale” reactors. The combined interpretation of data collected with standard investigation techniques (geological characterization, water level measurements, tracer testing, ground water sampling and analysis, etc.) and state-of-the-art methods would facilitate:

- Development of the best conceptual model of the process; and

- Validate the numerical model(s) by provide the necessary calibration targets.

Real-time monitoring in three-dimensions (3D) is a critical step on the validation of the conceptual model and numerical model of the industrial-scale process. Similar to that stated for the Characterization of Hydrodynamic Properties of a porous medium, numerical modeling without calibration to field observation is simply an interesting intellectual exercise with little to no value for the optimization of the actual process.

HGS’ TORPEC electrode is a multi-purpose measuring tool that allows the real-time, three-dimensional characterization of Temperature (T), Oxidation Reduction Potential (ORP), and Electric Conductivity (EC) of reactive transport process. In addition, HGS has developed electronic tensiometers for the measurement of pore pressure (suction) at any depth in aquifer materials as well as in leaching materials from crushed and agglomerated ore to run-of-mine (ROM) samples.

To date, we have deployed and tested our technology on a variety of settings and scales from relatively small lab columns (6-inch by 5-ft), to large silo leaching experiments (6-ft by 24-ft), to a pilot leaching test heap (twelve cells 24-ft tall by 120-ft by 240-ft), to an field-scale environmental remediation (60-ft wide, 280-ft long and 400-ft deep) pilot study.

Our work indicates that it is not sufficient to determine the solution migration paths, but it is also necessary to know the potential reactivity along such flow paths. The combined measurement of ER, suction, T and ORP is a powerful tool for monitoring reactive fronts moving through ore heaps and contaminated aquifer materials.

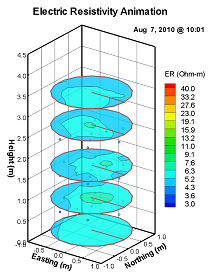

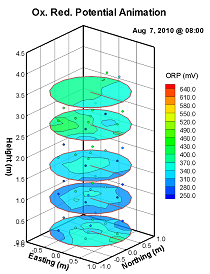

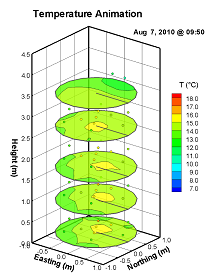

The figures below provide an example of time-lapsed snapshots from a real-time monitoring system while the video link (click on the snapshot) provides an animation showing the time-lapsed animation as generated from the TORPEC-electrode data base.

Two dimensional slices of Electrical Resistivity Data Set Two dimensional slices of Oxidation/Reduction Potential Data Set Two dimensional slices of Temperature Data Set

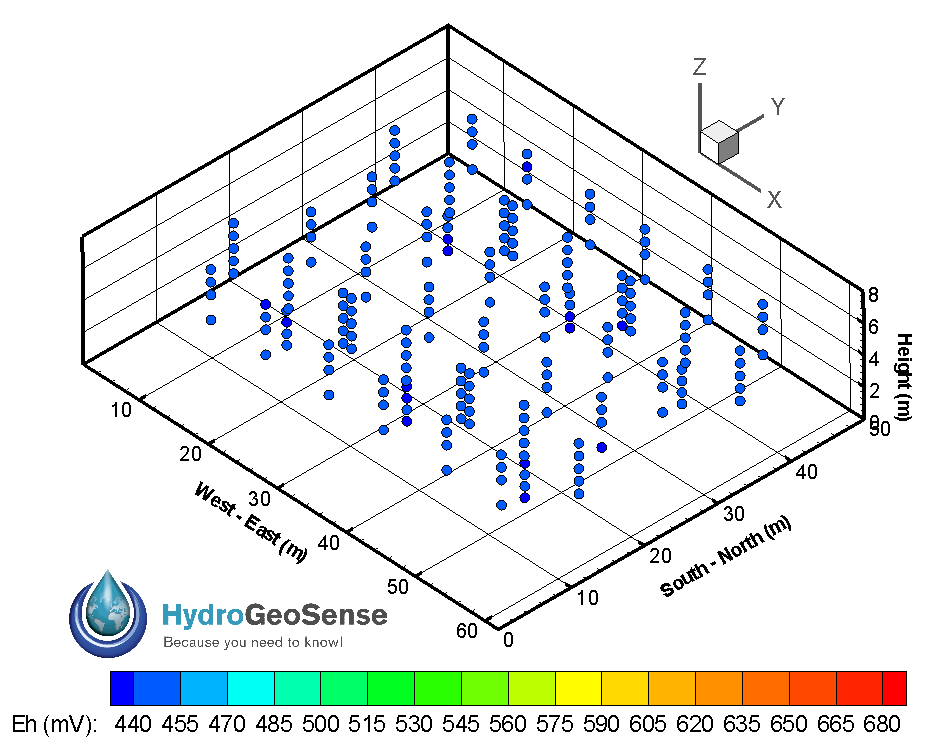

The following animation shows the daily evolution of the Eh (mV) for a demonstration project in which secondary copper sulfide was treated under a biological assisted leaching process. Each of the circles on the figure indicate the position of the sensors. In this application a total of 212 sensors where used to track the oxidation reduction potential in nearly real-time. Eh is an indicator of the state of oxidation within a heap and hence it can be used to:

- Indicate the effectiveness of the (bio-)leaching process at any given time and position within the heap;

- Define the rate of oxidation of sulfides (oxygen demand, exothermal energy release, etc.); and

- Guide operational decisions and facilitate optimization of the leaching process.